Digital Transformation: Maintain Your Food Manufacturing Edge

The food industry is a multi-layered and complex space. When it comes to food manufacturing there’s a labyrinth of pathways to attend to. With constant daily pressures on businesses, from razor tight margins to supply chain unpredictability, there’s little room for mistakes.

Digital transformation within a company’s framework has become an essential way to stay in the game – it’s no longer a question of whether a business will consider incorporating a digital infrastructure within its framework, but more about when it will do so.

“Almost nine in 10 food and beverage manufacturers and distributors plan to increase technology investment this year”

(CommBank Manufacturing Insights Report 2024)

With incredible pressure for businesses to become as streamlined as possible, food manufacturing and processing technology can offer much-needed reassurance that everything is running as smoothly as it can, without the risk of money being lost due to human error or excess wastage.

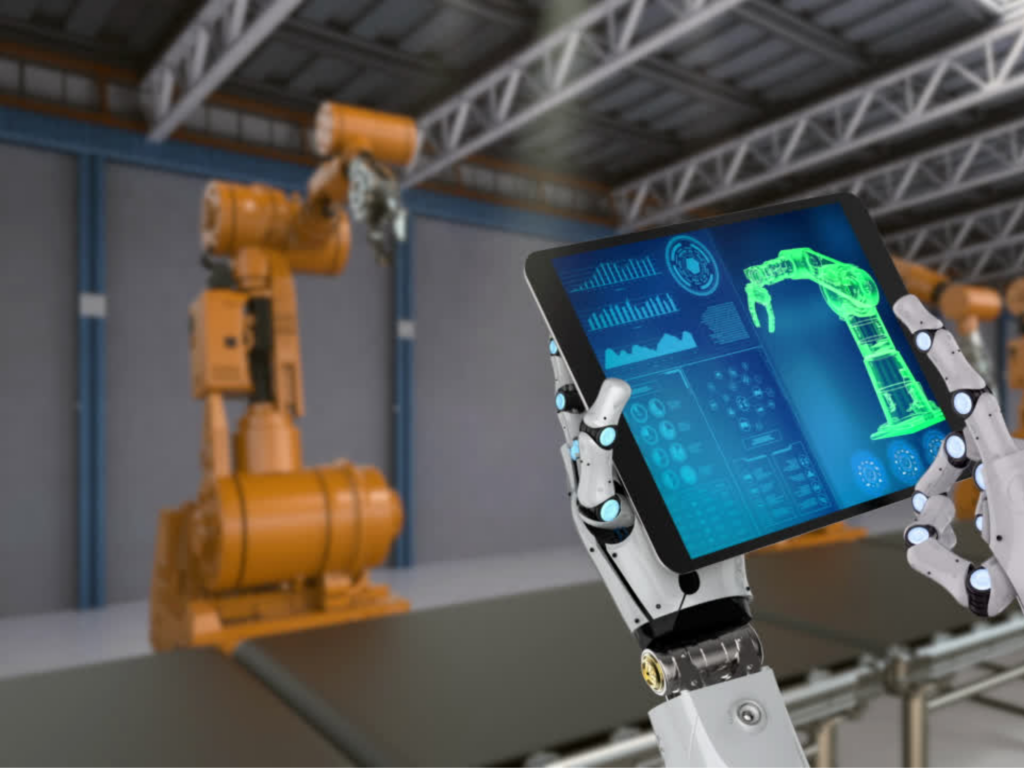

By implementing cutting-edge tech, operations can be made more efficient, while allergen management and recall processes can be streamlined, making them safer and more watertight. Additionally, improved technology systems can cut manpower costs significantly, having the potential to take on the roles of several staff members, often simultaneously.

The AI Revolution Is Real

These days it’s commonplace for businesses to be required to produce data from their inventories on request, within a matter of hours, sometimes minutes. Using traditional spreadsheets, this poses a real challenge. Inventory management software using AI technology is rapidly becoming a vital tool in not only speeding up the process of accessing a company’s data, but also to be able to store an entire inventory in one centrically accessible location.

For COYO, manufacturers of Australia’s first coconut yoghurt alternative made from organic dairy-free ingredients, it was a game-changing solution. Working with Fishbowl, specialists in AI-based inventory management software, they were able to transform their current inventory management processes. After working through an initial onboarding process, the company have not looked back, as they now relish the fruits grown from streamlining their operations to achieve greater efficiency, growth and market leadership.

COYO previously ran its inventory based on multiple, manually updated spreadsheets, making it complicated to keep track of up-to-date stock levels and costs. Everything was done by hand and, particularly during the COVD-19 pandemic, where demand and supply pressures fluctuated dramatically, the company found themselves needing an improvement in the way they managed their inventory if they were to be able to continue running a profitable business.

Sandra Gosling, COYO co-founder, elaborated on the issue, stating, “Prior to Fishbowl, COYO were having stock shortages every one to two weeks. I remember a lot of spreadsheets. And it was very difficult to see where the errors were happening. Fishbowl solved those problems for us.”

Sandra also reflects on how the business’ new centralised inventory system has saved them crucial time in retrieving data when necessary. “Fishbowl has positively impacted the company by centralising all of our information…if we have an issue with a product, time is of the essence to get that information out to the market to solve the issue.”

For COYO, retrieving data was something that took time and effort to achieve. Sifting through manually logged spreadsheets, it could take lengthy amounts of time to search for what they needed, sometimes days. Now, Sandra is proud to say that the data results can be gathered in around 90 minutes.

For companies yet to jump onto the AI-based technology revolution, the idea of scrapping an entire manual system (which perhaps took years to develop and is still firmly rooted in the foundations of the business), could feel like a daunting leap. For COYO, it wasn’t just about having access to transformational digital technology – with Fishbowl they were also buying into a complete system of support and expertise.

Simon Jupe, Fishbowl’s APAC Managing Director is well aware of the challenge facing prospective clients. “Implementation of inventory management software can be a transformative process for businesses of all sizes, but once [they] get past the initial change, and staff start becoming avid adopters of the new solution, that’s when [they] can effectively streamline and optimise operations, reduce costs and boost profitability.”

With AI-based inventory systems, managing data within a business really is a revolutionary change for a business. Almost overnight a company will gain the ability to oversee the running of their business in real time. Visibility is instant and everything can be traced back, leaving very little room for error and subsequently making supply chain issues a problem of the past. Stock checks, order management and costs can all be done in a fraction of the time without the worry of inevitable mistakes make due to human error.

For COYO, the implementation of Fishbowl inventory management software further impacted the company in ways they didn’t predict. “It has emerged as an invaluable asset to our entire organisation” says Sandra. “Sales, logistics, production, finance – we now operate as a unified whole. It has made an incredible impact, not to mention the environmentally conscious shift away from mountains of paper.”

Smarter Packaging

Automated palletising was developed over half a century ago, a combination of conveyor belts and industrial sorting equipment had been used to develop a tried and tested system that ultimately ‘got the job done’, but technology has moved swiftly over successive decades. The first robotic palletisers hit the market shortly after, with the 1980s making way for revolutionary articulated robot arms. Previously packages had to be of a uniform size for production lines to stack them onto pallets, now robot arms are able to navigate packages of varied dimensions.

Today, demands from supply chains, eCommerce and logistics mean that food manufacturers are increasingly under pressure to provide goods in the most efficient and cost-effective way, or they run the risk of losing business to competitors who can.

Collaborative robots, or ‘cobots’, are robots that can work side-by-side with human employees. They can take on a range of different tasks, from labelling to inspection of packages. The latest cobots are becoming increasingly more straightforward to operate, and they can even be programmed to offer businesses a tailor-made service specific to its individual production needs.

At Visy, a leading provider of packaging supplies and consumables across Australia and New Zealand, their range of high-speed robotic palletisers and depalletisers are offering companies both big and small the opportunity to increase production capacity and reduce costs. From optimising the packaging and supply chain model a business already has in place, to offering bespoke, integrated, end-to-end automation and technology solutions, Visy not only provide installation and maintenance but also on-going customer support.

Many other companies across the country (and indeed globally) are now realising the benefits of placing robots alongside human staff members on the factory floor. In May of last year, Priestley Gourmet Delights, a Brisbane-based dessert and savoury food maker, opened its new AI-powered facility, utilising autonomous robots. Fully equipped to handle a range of tasks, from stacking trays to monitoring temperatures and even managing ingredient levels, with an aim to improve the company’s productivity.

CEO, Xanny Christophersen continues to see the immense this new technology has had on the business. “The technology we’re harnessing will allow us to boost productivity while also enabling us to grow our people and support them to upskill. This project will create a substantial number of new jobs for Queenslanders, as well as add to the state’s economy.”

Priestly Gourmet Delights’ factory upgrade was made possible thanks to a recent initiative set up by the Australian federal government’s first ‘National Robotics Strategy’, which aims to support companies to invest in robot technology.

Federal Minister for Industry and Science, Ed Husic, has stressed the importance of these investments emphasising that “Lifting the adoption of these technologies will allow our manufacturers to produce higher quality products in less time and make them more internationally competitive.”

Sustainable Systems

We’re all striving to work in the most resourceful way possible. Efficiency in food manufacturing processes not only gets work done in the fastest time, but also in the most optimal approach, boosting revenue along the way.

Many companies are still using manually uploaded data, often riddled with human error, and more often still, this data is only saved hours, sometimes days after it’s been collected. How can a business operate efficiently under such erratic processes when demands from modern-day customers are unforgivingly high in regard product quality, uniformity and cost? OFS aims to take food manufacturing operators out of their straightjackets and into the driving seat.

Operations Feedback Systems (OFS) has been in business since 2006. Their mission is to assist manufacturing companies to operate more efficiently using their data-gathering software which has the ability to store information collected across the business, making it accessible to all employees.

OFS believe that access to highly accurate user-centric data, that’s gathered in real-time, will enable it to become a tool in itself, to subsequently empower food production operators to developing a culture of transparency, accountability and trust. Their aim is for businesses to achieve more sustainable and profitable growth through the delivery of this process.

Another key element to OFS is their focus on combatting waste. When evaluating waste, it can be considered in the traditional sense of unused materials ending up on the scrapheap, but it can also be looked at in terms of wasted time and even energy.

“Nearly 40% of industry respondents to an International Data Corporation (IDC) survey said their organisations anticipate prioritising sustainability over the following year —while almost 34% said efficiency and waste reduction would be a paramount priority”

(Food Engineering Magazine)

Shoni Even-Chaim, Founder of OFS, set up his business with the insight that it’s often the operators on the factory floor who need to be empowered with the right tools to do their work to the highest level of efficiency. “One of the things that I have learned in manufacturing is that the operators almost always know a better way to do things,” says Shoni. “After all, when the process jams up it is the operators on the factory floor who have to clean up the mess, not the decision-makers upstairs. However, in my experience, the voice of the operators is often the most ignored.”

For food and beverage manufacturing companies who are still on the fence when it comes to considering digital transformation as a means to sustain and expand their business, it’s worth reading up on some of the global statistics that are peppering the digital media space.

Consideration of what your options are in regard to which technology systems are worth investing in has become the minimum expectation for business owners if they don’t want to be left in the dust by their competitors.