CST’s clean green innovation for waste leader JJ Richards

Fine screening and compaction technology that can help halve hazardous waste transport costs while curtailing handling hazards and landfill dumping is being introduced to this year’s FoodTech Qld at the Brisbane Convention and Exhibition Centre July 28-30 2019

CST Wastewater Solutions (Stand C32) will feature its KDS multi-disc fine screening and compaction technology, of which an early adopter is Australian national waste management leader JJ Richards & Sons.

The technology processes pulped waste from JJ Richards’ partner Pulpmaster’s collection tankers into an easily handled and valuable resource for use in agriculture, horticulture and fossil fuel replacement.

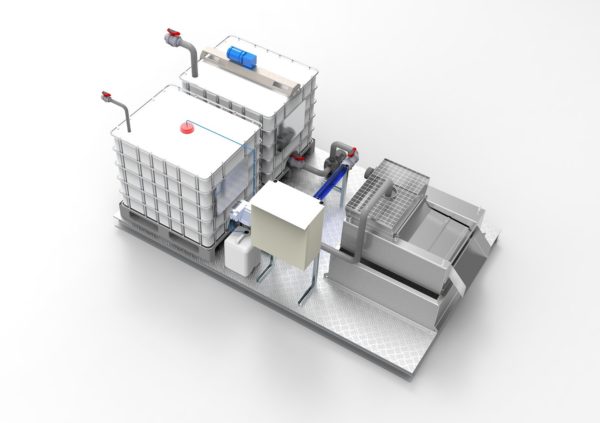

The plant where the KDS is deployed, in Seven Hills NSW, which already handles bulk waste from major customers including supermarkets, food shops, hospitals, schools and catering facilities. It uses KDS technology in its automated process that turns the pulped waste collected into a cake form. The form is more than 50 per cent lighter and dryer than the pulp and can be transported to users for half the cost of heavier and less hygienic output.

JJ Richards & Sons Pty Ltd NSW/ACT Operations Manager, Liquids, Mr Ben Martis comments on the systems cleaner greener energy benefits.

“The system not only disposes of an environmental headache and cost for responsible businesses – including high landfill costs and the high cost of transporting waste to somewhere remote, secure and non-harmful – but turns the problem into an environmental asset – and a cost saver.”

A modified tanker, used at JJ Richards Seven Hills site, with the said technology is able to:

- transforms food waste pulp into organic fertiliser

- generates green electricity from the biogas

- ensures zero waste goes to landfill

- curtails oil and grease entering sewer systems.

“Businesses love getting the reports on the environmental benefits of their waste disposal and recycling, because they can demonstrate benefits to the community, while also saving themselves substantial measurable costs,” says Mr Martis, who has been deeply involved in the design and proving of the Seven Hills plant, which features twin 28-ton filtrate receival tanks and similarly large vessels to process waste to the pH levels most ideal for recycling uses and injection into the ground as fertiliser.”

“There is a lot to like about the KDS system,” says Mr Martis. “It has very few moving parts, high-efficiency dewatering operation, uses little energy and doesn’t break down. It is a quality system.”

-

Stay up to date with the latest news, industry insights and FoodTech updates.

- Subscribe