In Conversation with a Palate Pioneer: Professor Jason Stokes

When enjoying a food or beverage product, it’s easy to take for granted the appealing texture and experience gained through its consumption. These days, demands on consumable products are incredibly high. From desires for longer shelf lives to adaptations around nutritional trends, these influences inevitably reshape a traditional product in countless ways, from mouthfeel to the way it’s digested within the body.

Behind the scenes of food and beverage manufacturing, painstaking work is ongoing to ensure that, as an example, a low-fat yoghurt remains both as rich and creamy in texture as its full-fat counterpart, or a potato chip that’s been baked rather than deep fried, still has the perfect ‘snap’ and delectable ‘crunch’.

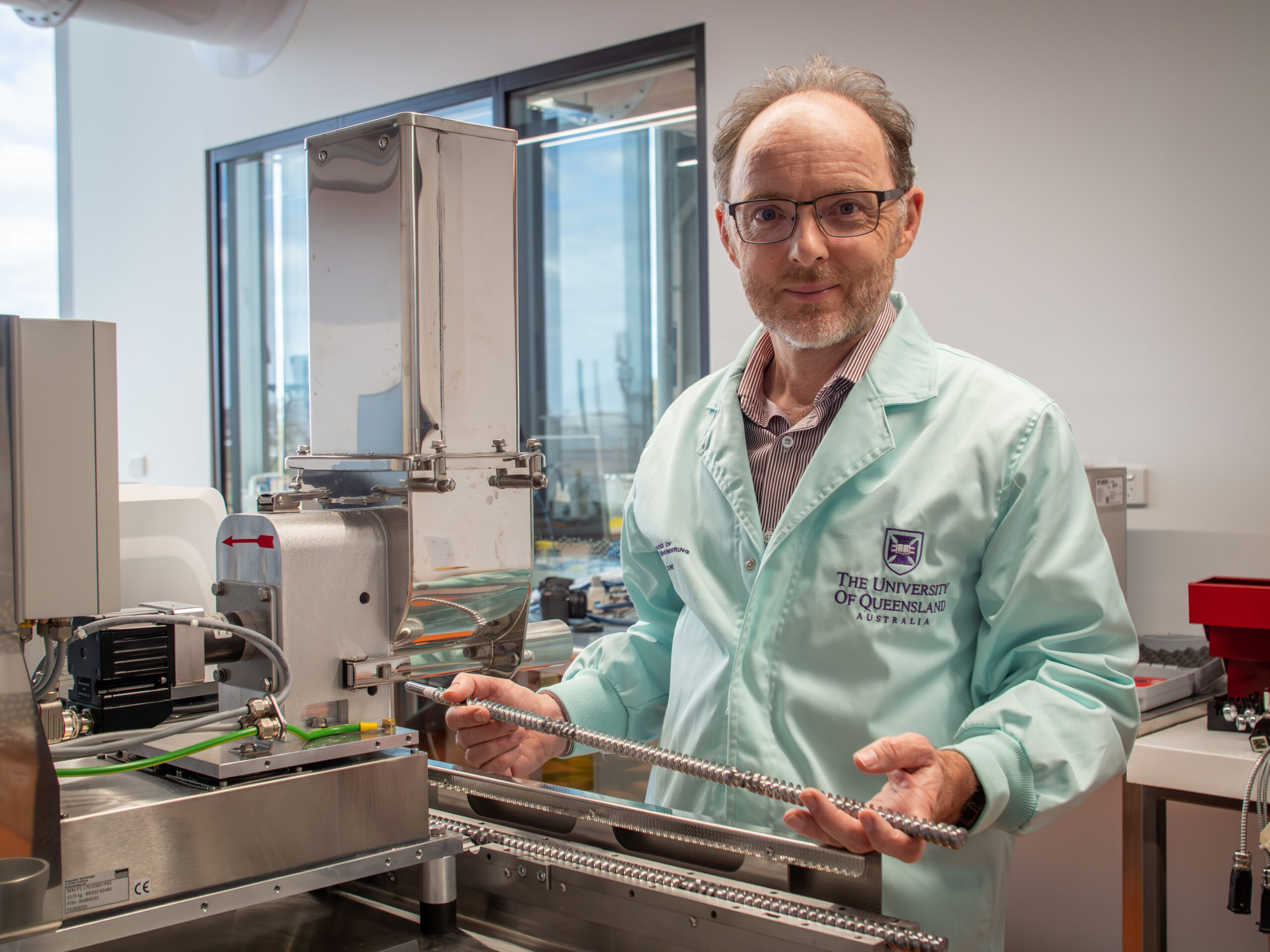

Meet Professor Jason Stokes, an academic scholar with a particular interest in uncovering how mechanical properties at the nano and microscale, influence macroscale rheology and lubrication – in layman’s terms, he’s an expert in breaking down the, often complex, components encapsulated in the products we consume. Using his expertise in this field, Professor Stokes aims to unlock an entirely new landscape, where endless possibilities in food and beverage innovation can be explored and developed.

An appetite for knowledge

Huge demands for brands to rapidly innovate and redevelop traditional products, appealing to different markets and accommodating changing trends, is just one of the expectations manufacturers encounter. Jason reveals how “It’s only when you have that underpinning knowledge base that you can ultimately achieve this. Knowledge is inherently linked to innovation, and it’s only really possible to rapidly develop product lines when you really know your ‘system’.”

A well-regarded Professor in the University of Queensland School of Chemical Engineering, Jason previously spent ten years as a research scientist and manager at Unilever’s Discovery Laboratory, UK. He also holds a BEng (Chem) and PhD from The University of Melbourne. These credentials have enabled him to work on a large portfolio of products to examine their, often subtle, characteristics in order to develop cutting-edge manufacturing techniques, to help brands to create new products that live up to consumer expectations.

Over the years, food and beverage products have been forced to adapt constantly due to changing trends. “Ten years ago, the big drive was to reduce sugar,” reflects Jason. “Then we had to reduce fat, then it was adding fibre and now more recently it’s about adding more plant proteins. Each time you’re doing these manipulations, you’re modifying the traditional tastes and textures you originally know that product to have. So maybe a yoghurt doesn’t feel creamy anymore, or something feels too rough or astringent.”

Investing in the Future – FaBA

In recent years, Jason joined an initiative known as the ‘Food and Beverage Accelerator’ (FaBA), working with a variety of companies, from start-ups to fully established brands and assisting them on a journey to bring new ideas and innovations to life. FaBA is all about supporting the food and beverage manufacturing industry to keep up with the ever-increasing demands from consumers.

“The Food and Beverage Accelerator spawned out of the Australian government’s Trailblazer Programme” says Jason, (referring to an initiative running from 2022 to 2026 with a budget of $370.3 million, that aims to enhance research capabilities, promote commercialisation and foster industry collaboration). “What it’s about, is helping to bring R&D [Research & Development] to Australian industry. It’s an exciting area of work, there are some really great innovators out there.

“I’m leading an area of the programme called ‘Premium Food and Beverages’, which is really trying to help companies to primarily develop their products. Basically, we’re the R&D hub to industry problems, addressing their challenges. People come to us for the plethora of knowledge needed to help solve some of these problems.”

Jason has joined forces with some of the industry’s most notable brands. As an example, he tells us about Fonterra, with whom he’s developed a working relationship going back several years. “Before I worked with them, I didn’t know much about dairy systems, but they consulted me because I had this this broader knowledge base around ‘structure, property and process’ that they wanted to tap into, and they wanted to have a new lens on their current systems.

“You don’t always want to have a dairy scientist looking at dairy systems. It’s actually good to get people with a physics background because you take a different approach at looking at things. You start to unravel the current system to then create levers for different ways of designing foods or changing the way different ingredients interact with one another.

“The current project with them is around high protein – how do we get a huge amount of protein into our dairy products? Often what happens is products become really thick or pasty; too much protein can cause a product to foam up and cause all manner of problems. Fonterra had already tried these processes and that was the result they were getting. So they approached us to help.”

The Innovation Gateway

Working on the R&D side of a business is vital these days if a company wants to experience significant long-term growth – it’s something that all companies could benefit from. For example, company might stumble across a great product that works with no issues, they put it to market and it’s successful. But, for the future longevity of that product (or indeed variations of it, to widen its appeal to a changing market), working alongside a scientist like Professor Jason Stokes could be integral to that long-term accomplishment.

To strip back a process, dissect it and really understand the science behind it is very much the map to discovering innovative, yet reliable product development.

“We try to connect product structure and properties with processing, that’s really critical in all of our work,” says Jason. “When we’re manufacturing products, and later sampling them, chewing, digesting, we’re starting to think about these connections. How food is digested and the process as it goes through, is it quickly digested or more slowly? This determines its nutritional profile – nutrition’s not just about the formulation of a product.”

Discover more at Food Tech Qld 2025

Professor Jason Stokes will be the keynote at this year’s FoodTech Qld. Join him in a discussion on “Shaping the Future of Food Manufacturing”, taking place on Thursday 19th June, 9.45-10.15am.

Discover more insights into this complex and dynamic area of work that’s proving itself so vital to the food processing and manufacturing industry as a whole. Here’s a flavour of the topics that visitors will have the opportunity to engage in during the presentation:

- Emerging Industry & Consumer Challenges — and Opportunities

Highlighting the evolving landscape of the food and beverage industry, including key challenges faced by producers and consumers, and the innovative opportunities these challenges present.

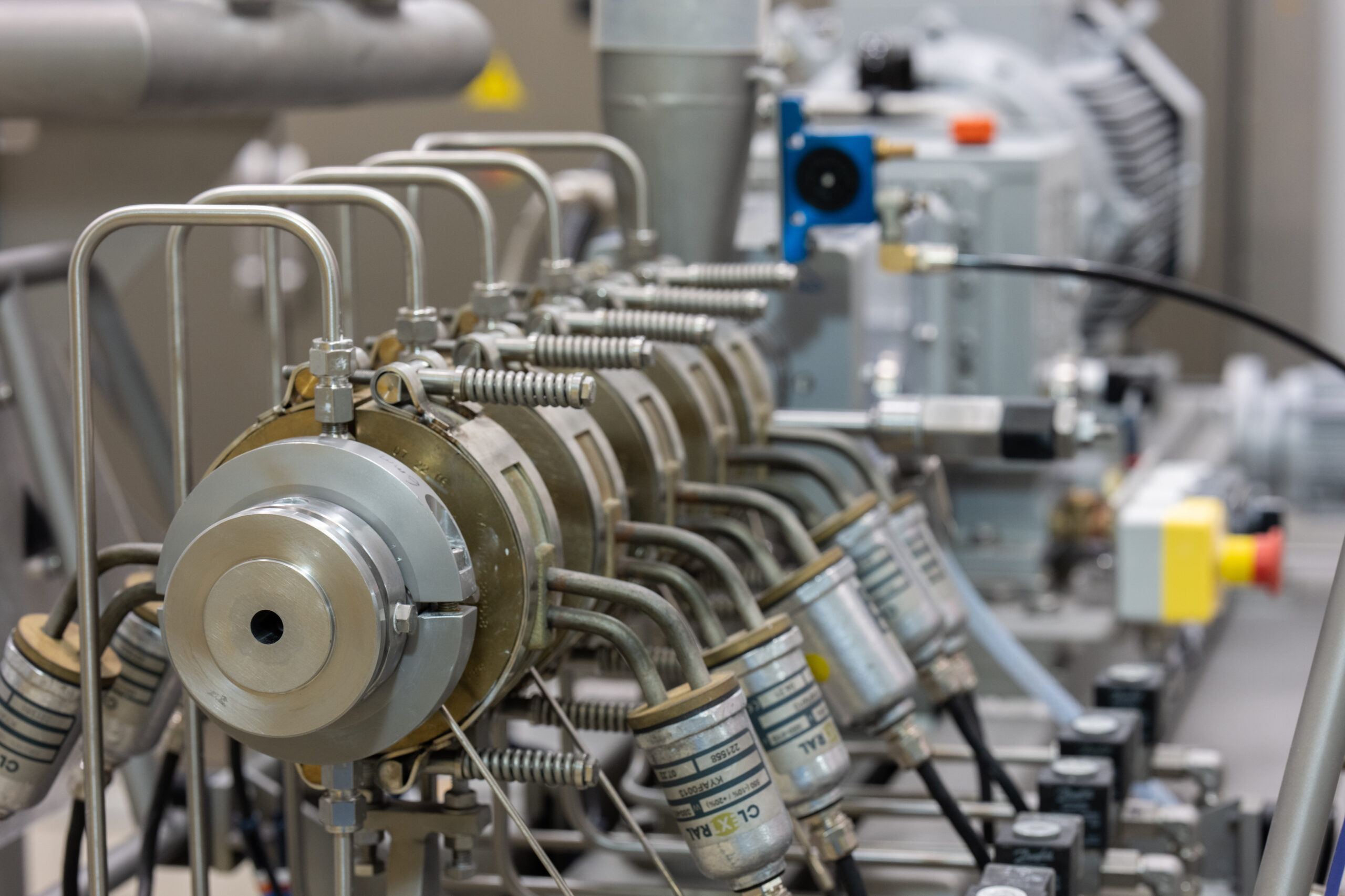

- Advanced & Emerging Technologies Transforming the Industry

A look into some of the cutting-edge technologies reshaping the industry.

- The Impact of Processing on Food Structure and Functionality

Investigating how different processing techniques influence food structure and, in turn, affect flow behaviour, stability, product format, sensory attributes, safety, nutrition, and digestibility.

- Food Extrusion and Processing for Structured, Nutritious, and Innovative Products

A dive into the role of extrusion and other advanced processing methods in creating next-generation food products that are both healthy, sustainable and appealing.

- Leveraging Food Physics and Advanced Technologies for Sustainable Design

How food oral processing and development of new characterisation tools in rheology and tribology are enabling the design of healthy, sustainable, and consumer-acceptable food and beverage solutions.

- Driving Innovation and Growth in Australia’s Food, Beverage and Ingredient Sectors

Highlighting the importance of strategic partnerships in fostering innovation and scaling growth across Australia’s agri-food ecosystem.